Although not visible, underlayments for hardwood flooring are essential to beautiful flooring. This material offers many benefits. Along with added support and sound protection, underlayment also improves the durability and longevity of your hardwood floors. To get the most out of the underlayment, however, you’ll need to select the right material. Find out how to choose the best underlayment for your new hardwood floors.

Purpose of Flooring Underlayments

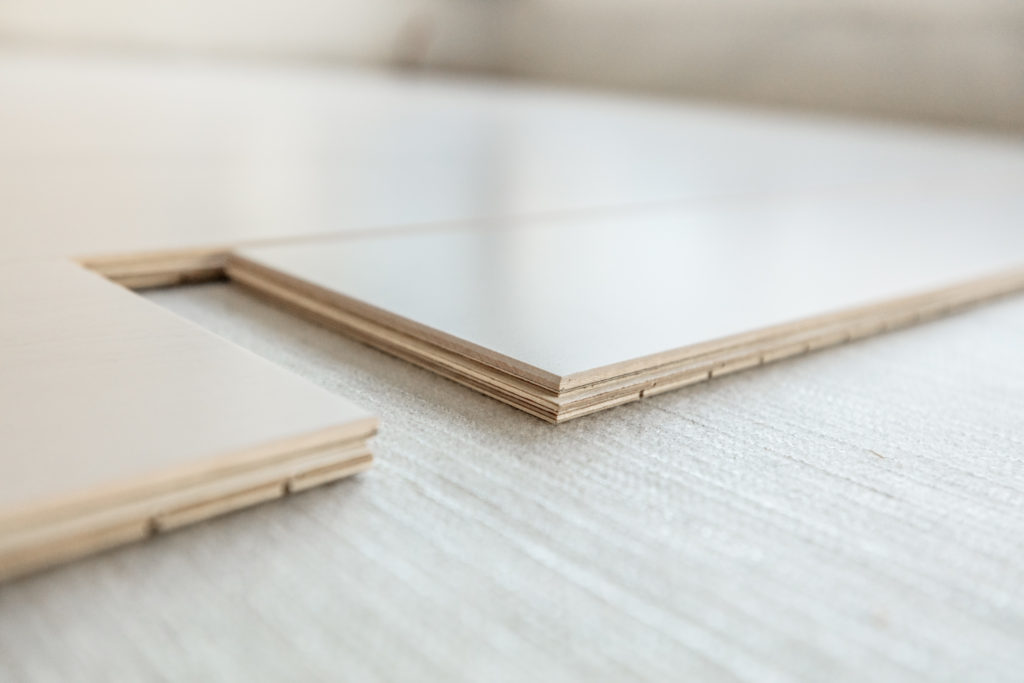

Flooring underlayment is a thin material that rests between the floor covering and the subfloor. Since underlayment is a catch-all term, it takes different forms depending on the flooring material it supports. There are two types of underlayments: rigid and soft. While the subfloor is part of a home’s framework and structure, the main purpose of the underlayment serves to provide a smooth, flat surface to allow for an easy installation of the surface flooring. Additionally, underlayment functions to deaden sound, to soften the feeling of the flooring underfoot, and to act as a moisture barrier. The primary purposes of underlayment are:

- Smooths Surface – Covers imperfections in the underlying subfloor

- Improves Structural Stability – A hard underlayment gives the entire floor better stability.

Material Options for Rigid Underlayments

Most floor coverings are best installed over a rigid underlayment applied over the subfloor:

- Plywood: A/C grade plywood is an excellent underlayment. A/C refers to plywood that has one relatively smooth face and one relatively rough side (for the bottom).

- OSB: Orient-strand board may be used as an underlayment for some floor coverings, but plywood is generally preferred for any flooring where a hard underlayment is recommended.

Material Options for Soft Underlayments

More installers are using soft flooring underlayments for hardwood but it should be noted that these are best used over an existing floor or in combination with a thin, rigid underlayment.

- Felt: Offers basic sound absorption and moisture barrier capabilities.

- Foam: Affordable and easy to install. Provides a high level of sound insulation.

- Rubber: Easily absorbs noises and disturbances. Easy to install due to its pliability and flexibility.

- Cork: Eco-friendly. Offers both temperature insulation and sound absorption.

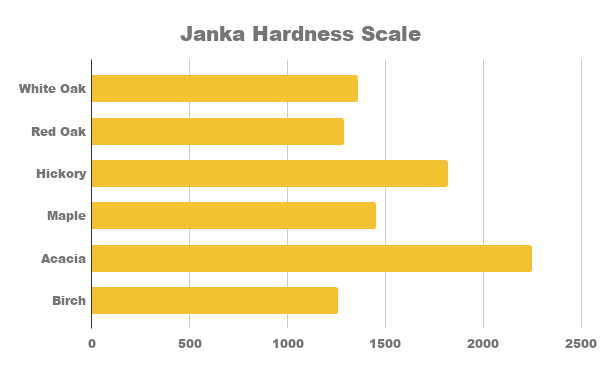

Hardwood Species Considerations

Flooring underlayments depend on the species as each has different qualities that pair better with different underlayment materials. To find the ideal match, consider the type of hardwood flooring you’re planning to install.

- Hickory: One of the hardest and most durable hardwood species, hickory flooring doesn’t need much help to withstand traffic and wear. Hickory flooring typically pairs well with flexible foam underlayment.

- Maple: Along with hickory, maple is one of the hardest types of wood flooring. It generally works best with foam or rubber underlayment, as both offer a moderate amount of support and insulation.

- Oak: Whether you choose white or red, oak flooring is on the softer side. Both types of oak pair well with rubber underlayment, which provides the insulation and absorption capabilities white and red oak need.

Evaluate the Subfloor Condition

While the hardwood species impacts the type of underlayment you’ll choose, so does the subfloor. Think about both the material and the condition of the subfloor as you make your decision. Subfloors that are damaged or uneven tend to work best with the flexible underlayments, as these materials can make up for imperfections in the subfloor.

If the subfloor is plywood, use an underlayment that’s semi-permeable. A semi-permeable underlayment allows both the hardwood floor and the wood subfloor to breathe without trapping mold and mildew or causing the material to rot. If the subfloor is concrete, opt for an impermeable underlayment instead. This type of material is moisture barrier, preventing water from seeping through the concrete and into the hardwood floor.

Consider the Purpose of the Room

In many situations, the room determines the ideal underlayment. Take into account that an apartment a higher level of a building may need a rubber underlayment, providing additional sound insulation and vibration absorption to prevent sound from traveling to the unit below. Similarly, a family room or entryway that experiences a high level of traffic may need a cork underlayment, as it is more supportive and can boost durability.

Confirm the Manufacturer’s Approval

Lastly, confirm the flooring manufacturer’s approval. Many manufacturers recommend certain types of underlayment for use with their products. Manufacturers may require you to install over their own underlayment in order to keep your warranty. Make sure that the underlayment’s material, thickness, and installation requirements are compatible with the flooring. After all, selecting the best underlayment for the hardwood flooring ensures that your floors will look fantastic, feel comfortable, and last for years to come.

Remember the tips above as you select flooring underlayments for hardwood. Once you’ve chosen the right underlayment, you’ll be one step closer to installing new hardwood floors and creating your dream home.